ABOUT PT. JANTOSSON MAKMUR LESTARI

PT. Jantosson Makmur Lestari is a machinery trading company and was founded in 2019 to serve the needs of food & beverage, coffee processing, cosmetic, pharmaceutical, petrochemical and tobacco segments. PT. Jantosson Makmur Lestari can serve your suitable machinery, spare parts and services.

AICROV SMART FILLING

BIG CONTAINER FILLING LINES

AICROV SMART FILLING

What We Do

AiCROV is the most innovative and dynamic company in the design, manufacturing, maintenance and optimisation of liquid filling systems for large-format containers between 1lt till 1.500lt and productivity up to 1,000 containers per hour, with accuracy and precision of up to 5 gr.

AICROV SMART FILLING

Reliable Productivity and Safety in Filling Machines

We place our clients first and never compromise safety in favour of productivity

AICROV PRODUCTS & SOLUTIONS

LSG - PLUG&FILL SERIES

LSC - PLUG&FILL SERIES

SP1 - PLUG&FILL SERIES

SP2 - PLUG&FILL SERIES

BRAMBATI S.P.A

Who We Are

Brambati SpA has been a protagonist in the field of food plant engineering since 1945 and particularly in the confectionary, biscuit, bakery, pasta, baby-food and coffee roasting industries.

BRAMBATI S.P.A

Brambati specializes in coffee and similar production plants

We can supply "turnkey" plants, from receiving the greenery up to feeding the packaging machines, through the phases of cleaning, storage, weighing, mixing, roasting, transport (with traditional mechanical transport or with the new generation slow transport) , grinding and degassing.

Our roasters have different sizes, from 5-7.5Kg/batch (20Kg/h.) to 600Kg/batch (3000Kg/h.) and can be of the traditional type (KAR or KAR-S models) or highly automated (BR models), allowing complete flexibility in the control of the coffee roasting process, adapting the characteristics of the roasting to the different needs of the customer.

Model KAR

Model KAR-S

Mod. BR

For each of our roasters we can supply the smoke burner, our mod. ECO, for the control of emissions into the atmosphere and the catalyst.

Even our mills can be of different sizes and types, the traditional type with a production of 100Kg/h. at 2500Kg/h. for Espresso, Moka and Filter coffee (fully automatic model KM series and modular model KL/KLL series) and the special type with a production of 50Kg/h. at 1000Kg/h. for Turkish and Greek coffee (fully automatic model KMT series and modular model KLL series).

Model KL3-200 / 600 / 1000 / 1500

Mod. KMT-600 and KMT-1000

Mod. KLL-600 and KLL-1000

Mod. KL3-100 LAB

With regard to the KL series, being modular, it can be with 1 single passage for models with 600-1000 and 1500 mm rollers or with multiple passages with 50-200-600-1000 and 1500 mm rollers, and can be adapted to grind products also different from coffee, such as spices, grains, etc.

Our production also includes the laboratory roaster mod. BRM-200 with prod. max 200 g.

Our group also supplies switchboards, hardware and software and all our systems can be fully computerized and automatic.

BRAMBATI PRODUCTS & SOLUTIONS

COMPLETE PLANT COFFEE PROCESING

GRINDING MACHINE

CONTROL ROOM

COMPANY

Dolzan Impianti has been a well-established company in the primary packaging sector since 1962. The long experience accumulated in more than sixty years of history has allowed the company to become a point of reference for the packaging of food and non-food products.

Passion and determination have led the business to reach an increasingly large pool of customers, involving as many as 90 countries around the world.

There are more than 120 customizable packaging combinations and are able to meet the needs of a wide range of food and non-food products.

The wide range of Dolzan automatic packaging machines and semi-automatic dosing machines allows you to package granular, powdery and liquid products in bags of different shapes and sizes.

The customer is satisfied with high-performance and customized packaging solutions, which guarantee maximum respect for the product during the packaging process.

FLEXIBILITY

Our flexibility allows our customers to choose from a wide range of solutions designed to meet different packaging requirements and needs, while always ensuring high performance for our systems.

Our packaging machines are available with different dosing systems and adapt to any sector: food, pharmaceutical, chemical, mechanical, oenological and construction and many others.

YUANG JIANG MACHINERY

FOODS & BEVERAGES FILLING LINES

YUANG JIANG MACHINERY

Beverage Filling Machine

Manufacturer Taiwan

Yuang Jiang provides different filling and packaging system for food, beverage and liquid products. We are Beverage Filling, Beverage Bottling Machine Manufacturer in Taiwan.

We have canning lines and bottling lines which are suitable for soybean milk, tea, juice, CSD, wine, olive oil, soybean sauce, vinegar, nutrition drinks …etc

In addition to being suitable for various kinds of products, our products range is fully comprehensive. From Depalletizer, Divider, Rinser, Filler, Capper, Seamer, Labeler, Case Packer, Weight Inspector to Palletizer, Yuang Jiang has just all it needs for a complete canning/ bottling & packaging line.

We also cooperate with our partners in this field very closely, which enable Yuang Jiang to plan turnkeys for our customers.

Quality and Efficiency are key factors of our services. We continue to focus our efforts on quality and always keep efficiency in our mind when planning every machinery line for our customers.

Yuang Jiang provides effective communication with our customers and customizes machine systems which fit their needs. We listen carefully to you, and take advantage of our professional knowledge and skills to provide you with our best serrvice.

#sleeve labeling system #Beverage Canning Lines #adhesive labeling system #OPP labeling system

YUANG JIANG MACHINERY PORTFOLIO

Beverage Bottling System

Rinser +Filler +Capper - Three in One

— perfectly connecting bottle rinsing, filling, and capping.

Our triblock bottling system minimizes the space needed and reduces energy consumption and pollution caused. It also decreases the situation of bottle falling, which enables the system to perform stably under high speed and operate with better hygiene quality and manufacturing efficiency.

To avoid the products to be filled being contaminated, all the parts which directly contact with the products are made of stainless steel of high quality. Also, the system is equipped with a specially designed water collecting trough that effectively collects and discharges the products remain in the system and cleaning liquid in sewer and keep the neatness of the factory ground.

—Rinsing—

We have two types of rinsers. One rinses bottles by disinfectant and sterile water. The other uses sterilized and compressed air to clean bottles. The two types are adopted depends on the character of the products to be filled.

For example, bottles for some products like pharmaceuticals and soy sauce cannot be rinsed by water. For these products, air blow type rinser is more suitable than water type rinser. Both water and air blow type rinsers have circulation circuit systems which are designed to recycle cleaning media in order to decrease the consumption and environmental pollution.

—Filling—

We provide several types of filler—gravity, piston and weighing filler for cold and hot filling of non-carbonated and carbonated beverages as well as oil products.All filling valves are designed to guarantee easy maintenance and ensure the top level of hygiene and cleanliness.

—Capper—

Cappers for ROPP, press on caps, plastic screw caps, lug caps and crown caps are available.

Our capping head with a magnetic clutch and pick and place device is especially suitable for capping plastic pre-threaded screw caps on PET, glass and PP containers. The cap screwing force is well controlled to reduce the wear of caps.

If you would like to increase production efficiency, our capper can be equipped with single or twin unscramblers and rails for multiple cap size which helps save the part changing time. Also, the hygienic treatment on the cap before capping can be offered by fitting UV lamps, liquid chemical, water washer or air blower.

beverage bottling system / liquid bottling system / sleeve labeling system

YUANG JIANG PRODUCTS & SOLUTIONS

TRIBLOCK FILLING MACHINE (RINSER + FILLING + CAPPER) FOR BOTTLE PET & GLASS

TWO IN ONE (FILLING + SEAMING) FOR CAN

VACUUM FILLER SYSTEM

HEFEI TAIHE INTELLIGENT TECHNOLOGY GROUP CO.,LTD.

A COLOR SORTER MACHINES

TAIHO MILESTONE

Hefei Taihe Intelligent Technology Group Co., Ltd (Taihe Intelligent) is a high-tech enterprise specializing in providing complete sets of intelligent equipment and services for visual recognition. The main products include four categories of agricultural and sideline food color sorting equipment, ore sorting equipment, intelligent packaging equipment, and intelligent loading robots, which are widely used in related processing fields. The products are sold in more than 80 countries and regions around the world.

The company was founded in 2004 and listed on the main board of SSE in 2017 (A share code: 603656). As a high-tech enterprise, provincial key software enterprise and innovative pilot enterprise, the company's professional R&D staff accounts for more than 20%, including more than 70 PhDs and masters; it has more than 400 patents and software copyrights and participates in the formulation of many national and industry standards. The company has established a national postdoctoral research station, provincial engineering technology research center, enterprise R & D center, and other innovation platforms; undertake the national science and technology innovation fund project, the national torch plan industrialization project, the major special projects of science and technology in Anhui Province, Anhui Province technology transfer plan and other major scientific research projects; recognized as the national industrial design center, national enterprise technology center, provincial manufacturing innovation center, city technology innovation center In 2018, "TAIHO" "Zengran” Packaging In 2018, Those two brands were recognized as Chinese well-known trademarks.

Based on the business philosophy of "green, health, safety and service", the company has continued to explore the development path of AI vision equipment application and established a competitive position in the sorting of rice, grains, tea, fruits and vegetables, plastics, industrial salt, ores,and other fields, establishing a professional and benchmark brand image. In the current national "double carbon" strategic objectives, the background of clean and efficient use of coal, the company will be intelligent coal dry coal separator as a strategic focus on the development direction, with technological innovation to focus on energy saving and carbon reduction, to promote green development.

In the future, Taihe will abide by the mission, full of pride, adhere to the core values of "customer first, quality excellence, innovation leading, fairness and justice", use technology and strength to gather strength, promote the upgrading of intelligent manufacturing industry, and practice the mission of "intelligent change the future, make work easier, make life better. "

PRODCUTION AND MANUFACTURING

Any imperfect process will result in the failure on the whole.

Taiho persisted in regarding the technological innovation as the power, striving for excellence, and providing the top quality product and service for the customers.

The company persisted in the production guideline of “quality first”, and the sound and perfect ISO9001:2008 quality management system, ISO14001 environmental management system, and OHSMS18001 occupation health safety management system, to ensure the high quality, environmental protection and safety of the company products.

The company introduced ERP system and improved the production efficiency. For the major products, the company executed the production mode of production according to sales, formulated the quick response mechanism, with the idea of “safety inventory” concurrently, expedited the product delivery efficiency, and improved the customer satisfaction.

The company ran the process quality control through the overall flow, established triple inspection system of “receiving inspection, production process inspection and finished product inspection”, created elaborately, and presented the high quality products to the customers.

technological packaging.

Multinational companies, as well as craft industries, find that TME is an attentive and competent partner that is familiar with the characteristics and problems of their production.

TME can provide its systems on all five continents. The path to internationalisation began in the mid 1980s and has constantly evolved thanks to the opening of sites in the North America and Brazil, without forgetting the agents and service network around the world.

TAIHO PRODUCTS & SOLUTIONS

Mini Series

AI Pro Series

AI Belt Series

TAIHO PRODUCTS & SOLUTIONS

Rice & Grains

Beans & Spices

Fruits, Vegetables & Others

OUR CONTACT

PT. Jantosson Makmur Lestari

Ruko 92 Avenix BSD Blok E No. 21, Jl. Raya Serpong - Lapan, Sampora, Kec. Cisauk, Kabupaten Tangerang, Banten 15345

+62-812-9000-0285

PT. Jantosson Makmur Lestari (JML) - YouTube

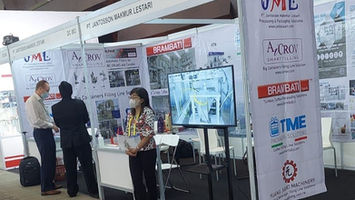

ALLPACK INDONESIA EXPO 2022

at JIExpo Kemayoran, Jakarta - Indonesia

12 - 15 October 2022

PT. JANTOSSON MAKMUR LESTARI

at Hall D, Booth DC003

We are presented to you as below:

Big container smart filling machines from AiCrov - Spain

A turnkey coffee processing machines from Brambati - Italy

Coffee filling and packaging machines from TME - Italy

F & B turnkey filling machines from Yuang Jiang Machinery - Taiwan

YUANG JIANG MACHINERY TRIP

TAIPEI & YILAN

YUANG JIANG MACHINERY FACTORY & CUSTOMER REFERENCE VISIT

THE AGENDA:

1. YJM FACTORY TOUR.

2. CUSTOMER REFERENCE VISIT.

3. FUTURE BUSINESS STRATEGY FOR INDONESIA MARKET.

29 March until 01 April 2023

YJM are able to supply you the filling line starting from 500 bph (linear filling line) up to 36.000 bph (PET bottle), 24.000 bph (glass bottle) and 72.000 cph (CAN) (All in the rotary filling line).

Products starting from still water up to particles.

BRAMBATI, TME, HOST MILANO 2023 & ITALY TRIP

Milan & Pavia

BRAMBATI, TME & HOST MILANO VISIT

THE AGENDA:

1. BRAMBATI FACTORY TOUR.

2. BRAMBATI & TME BOOTH VISIT.

3. FUTURE BUSINESS STRATEGY FOR INDONESIA AND SOUTH EAST ASIAN MARKETS.

11 October until 17 October 2023

Host Milano is the world exhibition dedicated to the catering and hospitality sector; an international hub active all year round that brings professionals together, constantly monitors all the sector's supply chains and consumer styles, presents in-depth analysis of current issues, best practices, international scenarios, produces news and global observatories, organises webinars and events all over the world.

Products starting from still water up to particles.

AICROV SMART FILLING MACHINE & SPAIN TRIP

BARCELONA & TARRAGONA

AICROV FACTORY, MEETING & CUSTOMER REFERENCE VISIT

THE AGENDA:

1. AICROV FACTORY TOUR.

2. CUSTOMER REFERENCE VISIT.

3. FUTURE BUSINESS STRATEGY FOR SOUTH EAST ASIAN MARKET.

16 until 19 October 2023

AICROV creates liquid filling systems for any type of industry requiring large containers.

We design, manufacture, maintain and optimize liquid filling machines for more than 15 years.

Our liquid filling machines guarantee the maximum productivity of the processes, prioritizing the safety of employees and offering post-sales technical support with great added value.

ALLPACK INDONESIA EXPO 2024

at JIExpo Kemayoran, Jakarta - Indonesia

09 - 12 October 2024

PT. JANTOSSON MAKMUR LESTARI

at Hall D, Booth DA010

We are presented to you as below:

Big container smart filling lines from AiCrov - Spain

A turnkey coffee processing plant from Brambati - Italy

A color sorter machines from Taiho - China

F & B turnkey filling lines from Yuang Jiang Machinery - Taiwan